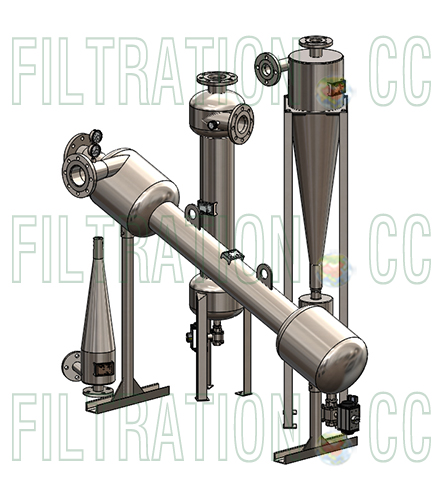

CSLS Centrifugal Solid-Liquid Separators

Introduction

CSLS Series Centrifugal Solid-liquid Separators (CSLS Separator for short) are a highly efficient solid-liquid separation tool. It separates precipitable particles from liquids by centrifugal force of liquid rotation. The separation efficiency of CSLS Separator depends on the particle density and the liquid viscosity,larger density of particles and lower viscosity of liquid, better separation efficiency;For high density particles larger than 40μm, its separation efficiency can exceed 98 percent.

CSLS Series Separators has no screens, slotted baffles, moving parts or filter media to cause unnecessary pressure loss or use of large volumes of backwash water. No maintenance is required, however periodic opening of the purge valve is necessary to dispose of unwanted solids. Purging can be done manually or automatically through the use of a purge package.

CSLS Series Separators can separate solid particles as small as 3μm, through multi-stage separation, the Separator can significantly increase eparation efficiency, it is also the excellent pre-filtration equipment.The pre-filtered liquid of the separator does not contain large particles and the solid concentration is greatly reduced, the cleaning cycle and filter media replacement time of the precision filtration system(e.g bag filter,core fitler,membrane filtration,RO system etc) connected with the separator are greatly prolonged,not only reduce labor intensity and system energy consumption, and Reduce personnel costs and expensive filter media replacement costs,our provides such kind of integrated filtration solutions.

Working Principle+

The liquid entering the separator is forced into a high velocity spiral flow pattern, developing centrifugal forces that cause particulates, sand, debris, and sludge to move to the outer edge of the separator. These particles moves downward in a spiral motion and settle out of the liquid into a collection chamber at the bottom. Clean liquid flows out of the separator at the vortex of the rotation, along the separator's axis.

Features And Adventags+

■ No rotating screens or fines boxes to clean or replace

■ Low and steady pressure loss,independent of separated crumbs and fines accumulation

■ Compact,space saving profile

■ Effective solids concentration for easy disposal

■ No routine maintenance or parts replacement, simple periodic solids purging only

■ Keeps all equipment operating at highest efficiency

■ Removal of 98% of solids 2.6 specific gravity and higher at maximum flow rate

■ wide range of applications, stand-alone flow1m3/h-2,000m3/h

■ Maximum particle size allowed for entry into the separator: 9 mm

■ Allowed to enter the separator containing up to 25000mg / l contaminated

■ Working pressure range: 1-16bar

Model Technical Parameters+

| Model | Dimensions mm | Flow Rate m3/h |

||||||

| A | B | C | D | E | F | G | ||

| SLSHN25 | 690 | 110 | 130 | 63 | 1" | 1" | 1" | 2-7 |

| SLSHN32 | 760 | 125 | 165 | 89 | 11/4" | 11/4" | 1" | 7-10 |

| SLSHN40 | 760 | 130 | 170 | 86 | 11/2" | 11/2" | 1" | 10-16 |

| SLSHN50 | 860 | 135 | 175 | 80 | 2" | 2" | 1" | 16-24 |

| SLSHN65 | 880 | 155 | 195 | 72 | 2 1/2" | 2 1/2" | 1" | 24-35 |

| SLSHN80 | 1040 | 167 | 215 | 80 | 3" | 3" | 1" | 35-65 |

| SLSHF100 | 1110 | 167 | 260 | 93 | DN100 | DN100 | 1" | 65-90 |

| SLSHF125 | 1310 | 225 | 270 | 80 | DN125 | DN125 | 1 1/4" | 90-110 |

| SLSHF150 | 1700 | 255 | 345 | 143 | DN150 | DN150 | 1 1/2" | 110-200 |

| SLSHF200 | 2300 | 355 | 345 | 165 | DN200 | DN200 | 1 1/2" | 200-380 |

| SLSHF250 | 2850 | 470 | 545 | 188 | DN250 | DN250 | 2" | 370-700 |

| SLSHF300 | 4380 | 660 | 610 | 240 | DN300 | DN300 | 2" | 560-900 |

| SLSLN/P100 | 1180 | 350 | 750 | 100 | 1 1/4" | 65-90 | ||

| SLSLN/P125 | 1240 | 350 | 790 | 100 | 1 1/4" | 90-110 | ||

| SLSLN/P150 | 1600 | 384 | 1010 | 100 | 1 1/2" | 110-200 | ||

| SLSLN/P200 | 2142 | 586 | 1320 | 100 | 1 1/2" | 200-380 | ||

| SLSLN/P250 | 2753 | 715 | 1790 | 100 | 2" | 370-700 | ||

| SLSLN/P300 | 4180 | 930 | 2850 | 100 | 2" | 560-900 | ||

| SLSLN/P350 | 4148 | 942 | 2856 | 150 | 3" | 650-1200 | ||

| SLSLN/P400 | 4148 | 942 | 2586 | 150 | 3" | 860-1600 | ||

| SLSLN/P450 | 4287 | 1029 | 2995 | 150 | 3" | 1100-2000 | ||

| NOTE: ■ CSLS Series Separators are designed for vertical installation while larger models are angled and floor or ground mounted. ■ The data in the table is for reference only, Contact us for more information |

||||||||

APPLICATIONS+

■ Source water liquids/solids separation (river water, lakes and wells)

■ Iron and steel enterprises in the production of iron-smelting, coking, steelmaking, rolling and other circulating cooling water treatment, nozzle and mold protection

■ Pre-filtration for bag, cartridge, screen, sand filters and centrifuges

■ Mining metallurgical water recycling, mineral recovery, pump protection

■ Mechanical processing coolant, cleaning agent recycling

■ Chemical production process water, sewage pre-filtration, recycling agent cycle

■ Oil industry, oil well water injection, offshore platforms, process water recycling

■ Paper&pulp industry, raw water, black liquor, recycled water process

■ Cooling tower water filtration, chemical reduction in treatment, increased efficiency

Download+